Contact us

Contact us

- : 0086-371-86151627 0086-371-86151827

- : 0086-371-86011881

- : [email protected]

- : [email protected]

- : bebonchina

Products

Products- Boiler steels

- High carbon steel

- High Yield steel

- steel for welded tubes

- General construction steel

- steel with Cr.,Mo.,Cr-Mo

- Steel for large diameter pipes

- Simple pressure vessels steel

- Steel for gas cylinders and gas vessels

- General purpose structural steels

- Steel for boilers and pressure vessels

- steel resistant to atmospherical corrosion

- Carbon steel and low alloy steel

- Fine-grain structural steels,normalised rolled

- weldable normalized fine grained pressure vessel steels

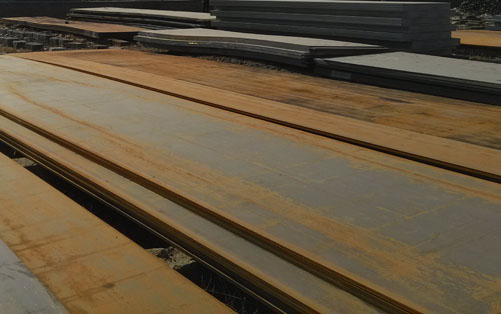

How to derust the steel surface?

During the processing of steel products, the oxide scale and rust on the surface must be chemically cleaned to expose the steel matrix to the steel products, and to more effectively improve electroplating, phosphating, oxidation (black hair blue), stretching, rolling, rolling Processing, anti-rust and other treatment effects.

The most common method of chemical rust removal is hydrochloric acid rust removal, because hydrochloric acid rust removal speed is fast and can be carried out at room temperature, so it is widely used. However, in actual operation, hydrochloric acid derusting has "over-corrosion" and "hydrogen embrittlement" phenomena, resulting in a large amount of acid mist, causing environmental pollution and social pollution.

The derusting additive is mixed with hydrochloric acid and has the following characteristics: at normal temperature, the derusting speed is fast and the derusting effect is good; it has the functions of penetration, dissolution, dispersion, peeling of scale and rust; Or exceed the Swedish derusting standard, Sa grade III, West Germany Be grade; good corrosion and mist suppression effect, due to the synergistic effect of various additives in the solvent, the steel will not produce over-corrosion and hydrogen embrittlement during the derusting process The acid mist standard is less than the concentration specified by the state, which is conducive to the post-treatment of rust removal; the cost is low, and the cost of rust removal is only about 0.5 yuan /m². After one ton of solution is used repeatedly, it can process about 5,000-7000 first-level rusted workpiece m², 1/10 of sand blasting and rust removal, 1/2 of pickling rust removal;

It has a wide range of applications and can be applied to steel products of various sizes and various components. It improves the working environment and conditions, reduces labor intensity, does not endanger the health of operators, and does not consume energy.