Application fields:

Q960E steel is widely used in aerospace, automobile manufacturing, construction engineering and other fields. In aerospace, Q960E steel is u

Q960E steel is an advanced material with outstanding properties, widely used in different fields. Its appearance has greatly promoted the development of materia

In order to meet the strength and impact properties of Q960E steel, the original grain size formed in the rolling process is very important to the performance o

S960QL steel plate is a high-strength low-alloy steel, commonly used in the manufacture of heavy machinery and equipment, S960QL steel plate is also widely used

Pickling: The process of using acid solution to remove scale and rust on the surface for S960QL steel plate is called pickling. It is a method of cleaning the m

S960QL European standard special alloy structural steel, belongs to quenched and tempered high yield strength structural steel, S means structural steel, 960 is

Due to its good plasticity, weldability and mechanical properties, Q235 steel is widely used in various fields, including:1. Construction work. Q235 steel is of

Q235 steel is widely used in construction engineering, automobile manufacturing, shipbuilding, petrochemical and machinery manufacturing and other fields. Howev

Q235 steel is generally used as soon as it is bought, and heat treatment is rarely done. There are several reasons for this analysis:1. The use of Q235 steel ge

At present, the demand for high-strength steel in the global market continues to rise, and the demand for high-strength steel in the fields of automobiles, mach

The material of FH32 steel plate conforms to the international classification society regulations, and has good welding performance and cold forming performance

FH32 steel plate is a high-strength structural steel plate used in ships and marine engineering. It has the following properties:1. High strength: FH32 steel pl

27MnCrB5-2 steel is a high-strength steel with extremely high ductility and impact toughness, and is widely used in the fields of machinery manufacturing and au

1. High strength: 27MnCrB5-2 steel has excellent strength through reasonable alloy ratio and heat treatment process. This makes it ideal for manufacturing parts

1. Name meaning of 27MnCrB5-2 steel

- 27 means the steel has an average carbon content of 0.27%.

- Mn means manganese, and its content is about 1%. The addition

The main factors of affecting non-metallic inclusions in SS490 molten steel are: the process control of smelting process and the quality of original paving mate

Non-metallic inclusions exist in SS490 steel as an independent phase, which destroys the continuity of the steel matrix, increases the inhomogeneity of the SS49

In the SS490 steel welding process, the original austenite grains around the weld grow abnormally by the thermal cycle, leading to poor weld quality. However, i

S420ML steel plate is a material used in structural engineering. Its materials include carbon, silicon, manganese, sulfur, phosphorus, chromium, copper, molybde

Perhaps you know what kind of material S420ML is, but do you know any knowledge about hot rolling and flaw detection of S420ML?Hot rolling of S420ML steel plate

S420ML steel plate is a European standard high-strength structural steel plate, which belongs to rolling and weldable fine-grained structural steel. S420ML stee

The cold rolling of QSTE500TM steel usually adopts longitudinal rolling, and the production process of cold rolling generally includes raw material preparation,

QSTE500TM is a low alloy steel with a series of excellent physical and chemical properties, widely used in the manufacture of automobiles, construction machiner

QSTE500TM steel and BW300TM steel are two different steels with different properties and uses. Here are some differences between them:1. Material grade

QSTE500T

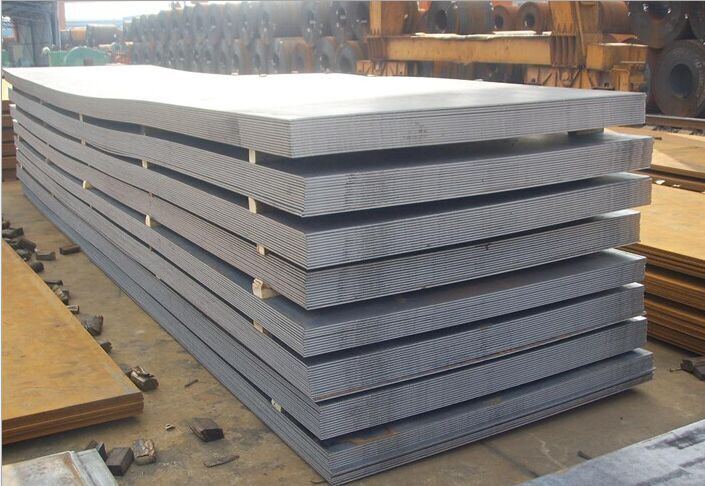

Steel plate cutting generally refers to the process of mixing industrial gas and oxygen to reach the cutting temperature, melting, blowing slag and dividing the

Contact us

Contact us

Products

Products News

News You are here : BEBON STEEL - News

You are here : BEBON STEEL - News Application fields:

Application fields: Q960E steel is an advanced material with outstanding properties, widely used in different fields. Its appearance has greatly promoted the development of materia

Q960E steel is an advanced material with outstanding properties, widely used in different fields. Its appearance has greatly promoted the development of materia In order to meet the strength and impact properties of Q960E steel, the original grain size formed in the rolling process is very important to the performance o

In order to meet the strength and impact properties of Q960E steel, the original grain size formed in the rolling process is very important to the performance o S960QL steel plate is a high-strength low-alloy steel, commonly used in the manufacture of heavy machinery and equipment, S960QL steel plate is also widely used

S960QL steel plate is a high-strength low-alloy steel, commonly used in the manufacture of heavy machinery and equipment, S960QL steel plate is also widely used Pickling: The process of using acid solution to remove scale and rust on the surface for S960QL steel plate is called pickling. It is a method of cleaning the m

Pickling: The process of using acid solution to remove scale and rust on the surface for S960QL steel plate is called pickling. It is a method of cleaning the m S960QL European standard special alloy structural steel, belongs to quenched and tempered high yield strength structural steel, S means structural steel, 960 is

S960QL European standard special alloy structural steel, belongs to quenched and tempered high yield strength structural steel, S means structural steel, 960 is Due to its good plasticity, weldability and mechanical properties, Q235 steel is widely used in various fields, including:1. Construction work. Q235 steel is of

Due to its good plasticity, weldability and mechanical properties, Q235 steel is widely used in various fields, including:1. Construction work. Q235 steel is of Q235 steel is widely used in construction engineering, automobile manufacturing, shipbuilding, petrochemical and machinery manufacturing and other fields. Howev

Q235 steel is widely used in construction engineering, automobile manufacturing, shipbuilding, petrochemical and machinery manufacturing and other fields. Howev Q235 steel is generally used as soon as it is bought, and heat treatment is rarely done. There are several reasons for this analysis:1. The use of Q235 steel ge

Q235 steel is generally used as soon as it is bought, and heat treatment is rarely done. There are several reasons for this analysis:1. The use of Q235 steel ge At present, the demand for high-strength steel in the global market continues to rise, and the demand for high-strength steel in the fields of automobiles, mach

At present, the demand for high-strength steel in the global market continues to rise, and the demand for high-strength steel in the fields of automobiles, mach The material of FH32 steel plate conforms to the international classification society regulations, and has good welding performance and cold forming performance

The material of FH32 steel plate conforms to the international classification society regulations, and has good welding performance and cold forming performance FH32 steel plate is a high-strength structural steel plate used in ships and marine engineering. It has the following properties:1. High strength: FH32 steel pl

FH32 steel plate is a high-strength structural steel plate used in ships and marine engineering. It has the following properties:1. High strength: FH32 steel pl 27MnCrB5-2 steel is a high-strength steel with extremely high ductility and impact toughness, and is widely used in the fields of machinery manufacturing and au

27MnCrB5-2 steel is a high-strength steel with extremely high ductility and impact toughness, and is widely used in the fields of machinery manufacturing and au 1. High strength: 27MnCrB5-2 steel has excellent strength through reasonable alloy ratio and heat treatment process. This makes it ideal for manufacturing parts

1. High strength: 27MnCrB5-2 steel has excellent strength through reasonable alloy ratio and heat treatment process. This makes it ideal for manufacturing parts 1. Name meaning of 27MnCrB5-2 steel

1. Name meaning of 27MnCrB5-2 steel The main factors of affecting non-metallic inclusions in SS490 molten steel are: the process control of smelting process and the quality of original paving mate

The main factors of affecting non-metallic inclusions in SS490 molten steel are: the process control of smelting process and the quality of original paving mate Non-metallic inclusions exist in SS490 steel as an independent phase, which destroys the continuity of the steel matrix, increases the inhomogeneity of the SS49

Non-metallic inclusions exist in SS490 steel as an independent phase, which destroys the continuity of the steel matrix, increases the inhomogeneity of the SS49 In the SS490 steel welding process, the original austenite grains around the weld grow abnormally by the thermal cycle, leading to poor weld quality. However, i

In the SS490 steel welding process, the original austenite grains around the weld grow abnormally by the thermal cycle, leading to poor weld quality. However, i S420ML steel plate is a material used in structural engineering. Its materials include carbon, silicon, manganese, sulfur, phosphorus, chromium, copper, molybde

S420ML steel plate is a material used in structural engineering. Its materials include carbon, silicon, manganese, sulfur, phosphorus, chromium, copper, molybde Perhaps you know what kind of material S420ML is, but do you know any knowledge about hot rolling and flaw detection of S420ML?Hot rolling of S420ML steel plate

Perhaps you know what kind of material S420ML is, but do you know any knowledge about hot rolling and flaw detection of S420ML?Hot rolling of S420ML steel plate S420ML steel plate is a European standard high-strength structural steel plate, which belongs to rolling and weldable fine-grained structural steel. S420ML stee

S420ML steel plate is a European standard high-strength structural steel plate, which belongs to rolling and weldable fine-grained structural steel. S420ML stee The cold rolling of QSTE500TM steel usually adopts longitudinal rolling, and the production process of cold rolling generally includes raw material preparation,

The cold rolling of QSTE500TM steel usually adopts longitudinal rolling, and the production process of cold rolling generally includes raw material preparation, QSTE500TM is a low alloy steel with a series of excellent physical and chemical properties, widely used in the manufacture of automobiles, construction machiner

QSTE500TM is a low alloy steel with a series of excellent physical and chemical properties, widely used in the manufacture of automobiles, construction machiner QSTE500TM steel and BW300TM steel are two different steels with different properties and uses. Here are some differences between them:1. Material grade

QSTE500TM steel and BW300TM steel are two different steels with different properties and uses. Here are some differences between them:1. Material grade Steel plate cutting generally refers to the process of mixing industrial gas and oxygen to reach the cutting temperature, melting, blowing slag and dividing the

Steel plate cutting generally refers to the process of mixing industrial gas and oxygen to reach the cutting temperature, melting, blowing slag and dividing the